Post Curing of Silicone Tubing

Post Curing is the process of heating up the silicone tubing in an oven at a given temperature for certain amount of time. The lowest and highest temperatures used in Jehbco for post curing is 160˚C and 200˚C. Post curing process helps to remove the volatiles from the manufactured products.

As the name indicates, post curing is the secondary curing process in the silicone manufacturing. The Post curing helps to further cross link the polymer chains to enhance mechanical properties, thermal and chemical resistance. Post curing of silicone helps to improve the physical characteristics of the material. All silicone elastomers go through a peroxide silicone curing using peroxide-based chemicals or a platinum cure using a catalyst. Even though the rubber is in a finished product format, it is still not a stable state. Few by products /volatiles from the chemical process is left with the silicone after the initial cure. These volatiles will be removed during the post curing process. Inadequate or poor post-cure may cause bubbling, delamination and unappealing sticky surface deposits.

In a typical post curing process, the temperature is adjusted between 160˚C and 200˚C for a period of 2-6 hours. The time and temperature may be altered depending on the application. Post-curing ensures the product remains dimensionally stable. Post Curing also helps to reduce /eliminate the outgassing process. The main reduction in mechanical properties of the silicone occurs in the first couple of hours at a service temperature. Post-curing brings the silicone to a state where its degradation rate is minimized, ensuring long-lasting performance with consistent quality.

Apart from all the advantages mentioned above, post curing also helps to enhance the thermal stability of silicone rubber. Allowing it to maintain its properties at higher temperatures without degrading. For silicone products that come into contact with high-temperature surfaces, undergoing the post-curing process is highly beneficial as it posts curing will produce a highly thermal resistant product.

By completing the cross-linking process, post-curing improves the silicone’s resistance to chemicals and solvents. This is particularly important in environments where the material is exposed to aggressive substances, such as in pharmaceutical or food processing equipment. Current manufacturers recommendation from Jehbco’s supplier is to post cure at 200 degrees Celsius for 4 hours for pharmaceutical and food applications.

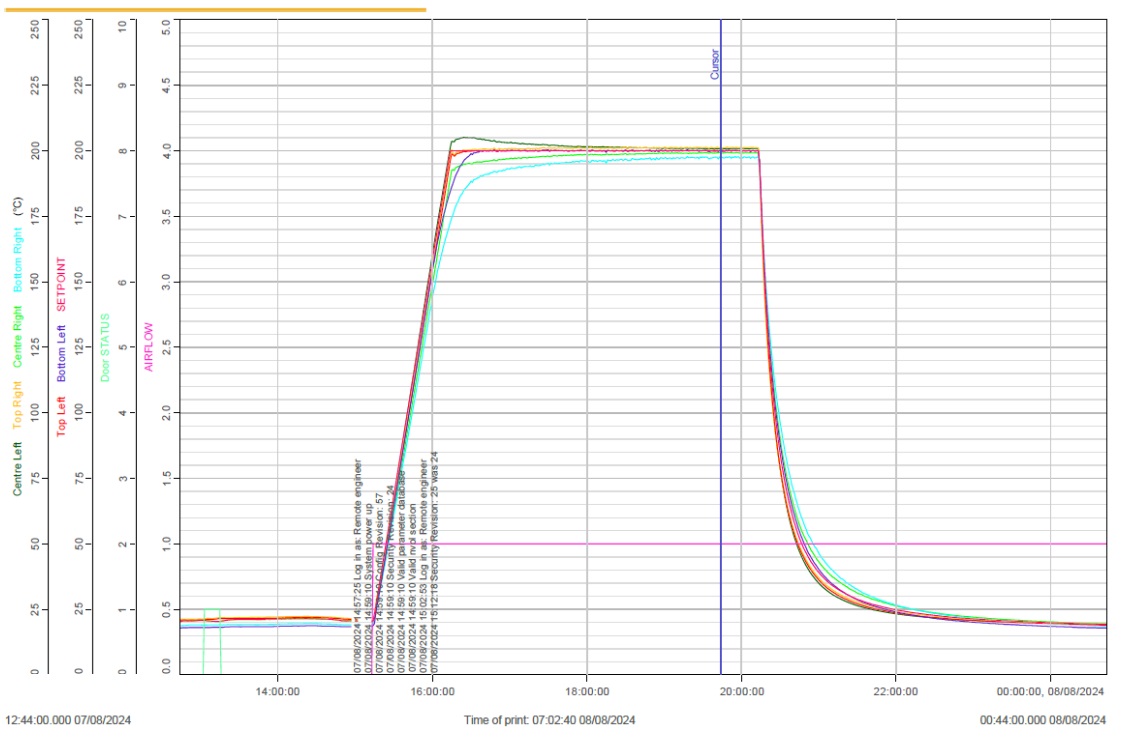

Oven temeprature records which shows the temeprature distribution in different locations of the oven

Jehbco is dedicated to meeting customer silicone requirements despite the costliness of post curing. The company employs oven curing or all post curing needs, a process involving placing manufactured goods in an oven under carefully controlled temperature and time conditions. Jehbco utilizes two new ovens from Steridium for this purpose, ensuring efficient post curing operations. One oven is exclusively used for platinum curing, while the other is dedicated to peroxide curing. This segregation guarantees that there is no cross contamination during the post curing stage at Jehbco. The Airflow specification for Jehbco’s new ovens is 20,000 liters/minute. Thermocouples are positioned in nine locations on both sides of the oven to monitor and ensure even heat distribution throughout. The oven requires only 30 minutes to reach the desired temperature. Customers may request post curing of silicone from Jehbco if needed. Jehbco will monitor the temperature readings from the ovens to ensure the post curing process is executed effectively. Committed to delivering top-quality products, Jehbco prioritizes maintaining customer trust and satisfaction. The oven picture and the sample temperature records are added in the annex section of the article.

References

- https://rdabbott.com/wp-content/uploads/2017/08/Dow-Corning-Post-Curing-Silicone-Elastomers.pdf

- https://shorehoses.com/news/importance-of-post-curing-of-silicone-products/

- https://www.adhesivesmag.com/articles/99586-post-cure-advantages-for-silicone-elastomers-and-adhesives

- https://www.wacker.com/h/medias/7562-E-0323-final.pdf