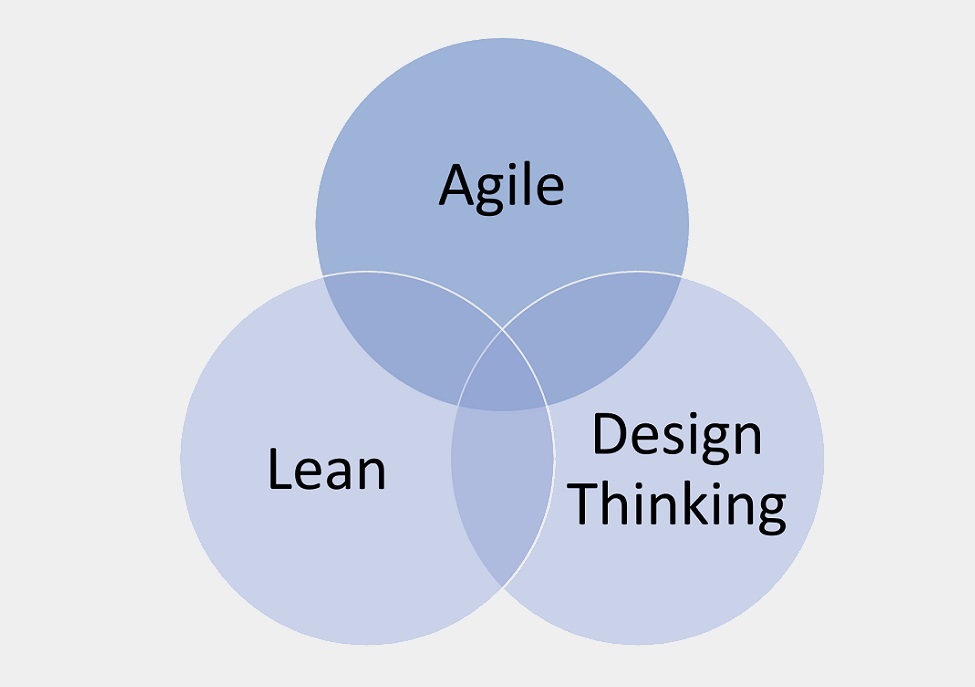

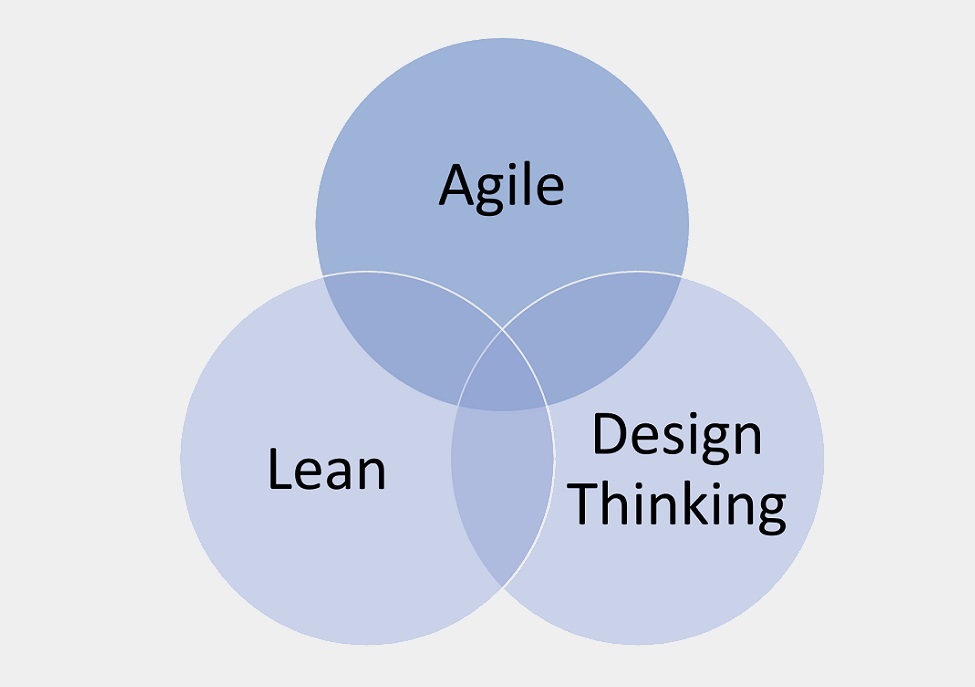

Agile, Lean and Design Thinking

Agile ‘philosophy’ was developed in attempt to develop products in a simple, fast and efficient manner. The process brings together a multidisciplinary team, thus facilitating productive interactions. As part of the process, it is necessary to include the customer as a lens for realising and validating decisions. This approach initially started within technology companies and has now made its way to manufacturers customer contacts the company directly, the factory is notified, and the manufacturing process begins within hours. Each product is customer-built, and all necessary quality testing is carried within one day. Overall, the customer receives his customised product in less than 5 days1. This approach does not only provide a customer-focused product design, but also facilitates higher levels of cooperation within supply chains, ensuring that production reaches its full potential.

Intersection of Agile Philosophy, Lean Manufacturing and Design Thinking Diagram – Jehbco Silicones Manufacturing

Lean manufacturing is based on the principle of eliminating unnecessary work, with the aim to combine flexibility, quality and low costs2. It focuses on the elimination of waste, maximising value addition, and reducing the essential support in an organisation’s processes.

Design thinking puts the customer at the core of operations, thus making products intuitive for the customers to use. The formalised process of design thinking is to discover, define, develop and deliver. Teams are encouraged to go broadly research in both the ‘discover’ and ‘develop’ phases. This process facilitates innovation and results in products that provides ultimate user-experiences.

Combining ‘Agile’, ‘Lean’, and ‘Design Thinking’ results in an efficient, sustainable, and highly-responsive business that puts its customers at the heart of their operations.

Jehbco always puts the customer first; when a customer asks about a silicone rubber through the sales department, our multi-disciplinary team of specialists are notified. The team assess the suitability of the product range for the application of interest. Jehbco works closely with the customer to achieve the best possible choice. At times, the specialists provide custom-built silicone rubber products for customers with unique applications.

In principle, Jehbco is adopting best business methodologies to provide customers with high-quality, low-cost, and customised silicone rubber products.

References

- Agile Manufacturing – Case Studies Available from: http://agilemanufacturing.weebly.com/case-studies.html.

- Idea. Lean Production. 2009; Available from: https://www.economist.com/news/2009/10/19/lean-production.