Low Compression Set in Silicone Rubber and its Application in Seals

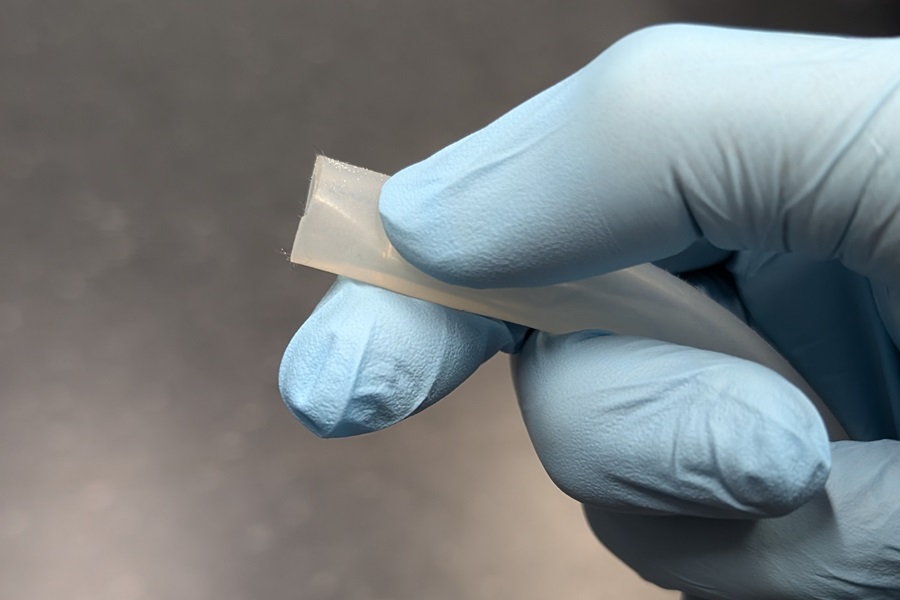

Silicone rubber is well known for its excellent elastomeric properties, exhibiting outstanding elongation at break values and rebound resilience. Due to these properties, silicone is an ideal material for producing a wide variety of seals and gaskets which readily form stable and durable mechanical seals upon applying pressure.

A crucial parameter in the sealing performance of silicone is the compression set. In a sealing application, mechanical force is applied on the silicone seal to compress it between two surfaces. The elastomeric properties of the silicone causes it to bounce back to its original shape, and tightly forms a seal against the two surfaces that obstructs any flow of liquids and gasses. However, upon long-term compression, the silicone can lose a fraction of its shape memory, becoming permanently deformed and will no longer fully bounce back to its original shape. This permanent deformation after prolonged mechanical stress is applied and then released is known as the compression set. If a material has a high (poor) compression set, a large proportion of its original shape memory will be lost upon prolonged compression, which can cause sealing failure. Thus, compression set is a crucial property in sealing design as it indicates the ability of the seal to maintain its shape and sealing properties over extended periods of time.

Compression set of silicone elastomers is typically measured using conventional standards such as ISO 815-1 B and ASTM D395 B. In these standards, standardised samples of silicone are placed between two metal plates which are then compressed, using gauge blocks to calibrate a fixed deformation distance, which is typically 75% of its original height. The entire apparatus is then placed in elevated temperatures to promote accelerated ageing, and compression set is provided at the testing values. For silicone rubber, a compression set testing period of 22 h at 175°C is often used. For related materials such as silicone sponge, separate testing samples and test durations are outlined in ASTM D1056.

Solid silicone rubber exhibits excellent compression set values, typically between 10 – 30 % depending on the hardness and grade used, which is significantly lower than other elastomers such as EPDM or neoprene. In addition to an excellent low compression set, silicone is a chemically inert material, has outstanding heat resistance, and is safe for use in contact with food, and is thus the material of choice for sealing applications in high temperature environments, and food and medical grade industries. More information on silicone seals, mechanical properties and elastomeric behaviour is available on our articles page.