Mechanical Testing & Simulation

At Jehbco, research is constantly carried out to understand the behaviour of silicone rubber and its properties under various conditions to achieve control over the entire product lifecycle. Silicone rubber is a viscoelastic amorphous polymer which simultaneously exhibits internal resistance to flow as well as molecular positional memory under deformation over a temperature range specific to the material. Thanks to these properties silicone rubber can be extensively used in sealing applications.

Mechanical sealing is important in equipment with movable parts. The compartmentalisation between sections of machinery or equipment is achieved using rubber gaskets and seals.

For the manufactured silicone rubber product to perform the functions it is designed for, it should retain the design properties under operating conditions. The form or shape of the seal or gaskets, deformation behaviour, hardness, coefficient of friction, and compression set define the final properties of the product.

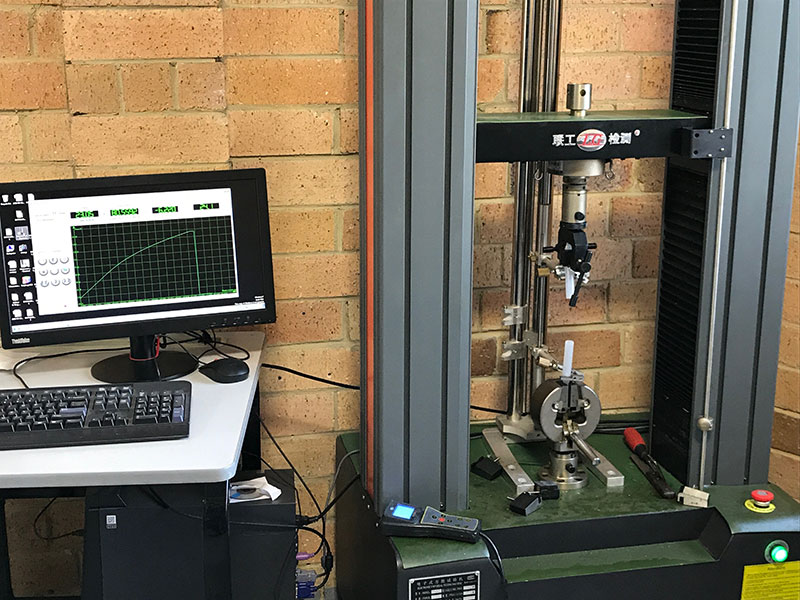

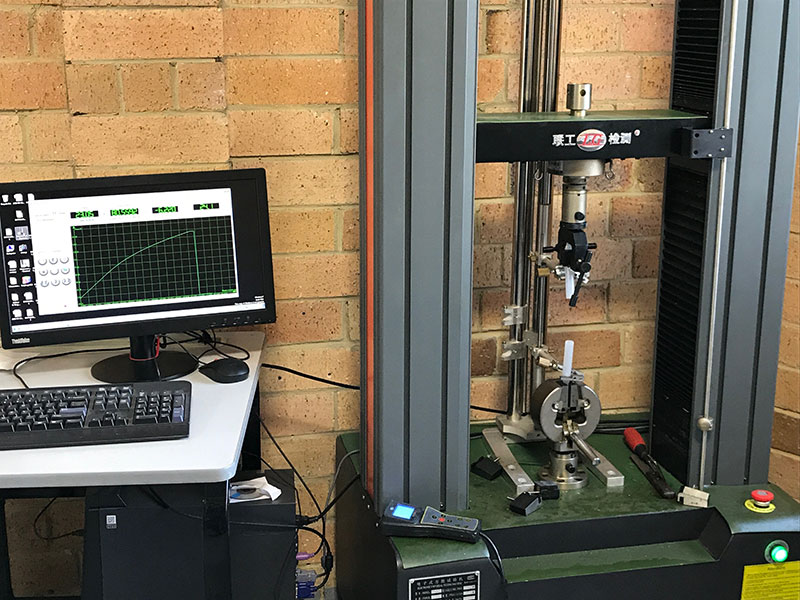

Tensile testing machine

In comparison to materials that behave linearly under load, understanding viscoelastic materials is challenging. Below are the differences between stiffness, strength and hardness and their corresponding indicating parameters which are generally used to describe the property of the rubber product.

- Stiffness is an indicator of the tendency for an element to return to its original form after being subjected to a force. (Compression set)

- Strength measures how much stress can be applied to an element before it deforms permanently or fractures. (Tensile strength)

- Hardness measures a material’s resistance to surface deformation. (Shore hardness)

Hyperelastic numerical models are used to represent various non-linear material behaviour under different conditions. Hyperelastic models for expressing the behaviour of elastomers are modelled as incompressible (i.e. changes in shape but the overall volume remains same), isotropic (i.e. internal properties such as stress are uniform in all directions) and homogeneous. The model is validated against the customer’s specimen or initial test piece developed at our facility. Finite element analysis is carried out using SolidWorks using which the developed Hyperelastic model is computationally tested. The results are then indicative of the stiffness, strength and hardness characteristics which is used in product development.

Our understanding of non-linear behaviour of the material is key to our product development capabilities. Developments are constantly being made to pour in-house testing facility improving both simulation and physical testing capabilities.

We have developed a software to calculate custom size of O-rings and butt-joined chord type gaskets, adding to Jehbco’s expertise in providing solutions for non-standard applications. The software is a result of comprehensive design-engineering and experimental testing carried out by our research and development team.

The mechanical testing and research facility at Jehbco is equipped to meet industrial product testing standards for variety of applications, making sure the customer gets the best engineered product.

For further information or advice about our product testing and development, please review Jehbco’s articles and contact us with any questions.

References

- Villasenor-Ochoa, H. (2017). Engineering Fundamentals Refresh: Strength vs Stiffness vs Hardness | Fictiv – Hardware Guide. [online] Fictiv.com. Available at: https://www.fictiv.com/hwg/design/engineering-fundamentals-refresh-strength-vs-stiffness-vs-hardness [Accessed 25 Jul. 2018].

- Dickey, R. (1973). Nonlinear elasticity. New York [etc.]: Academic Press.

- A.N., G. (1994). Science and Technology of Rubber. 2nd ed. ACADEMIC PRESS. Published by Elsevier Inc., pp.1-22.