Room temperature vulcanising (RTV) silicone sealants are a popular and versatile joining material frequently used in the construction industry. These ready-to-use silicones cure at room temperature by reacting with moisture in the atmosphere, forming a strong and stable join. However, this curing process produces unwanted, toxic by-products which are released into the immediate surroundings. Excessive short term and long term exposure to these by-products have significant associated health risks, including suspected carcinogenicity and damage to the eyes, skin and respiratory system.

The most common kind of RTV silicone sealants are acetoxy and neutral curing silicones. Acetoxy curing silicone sealants produce acetic acid upon curing, emitting a pungent, sour odour resembling vinegar. While these sealants are commonly used for domestic applications and glass or ceramic substrates, the corrosiveness of acetic acid makes acetoxy curing RTV silicone unsuitable for many substrates used in construction applications. Neutral-curing silicones do not form corrosive by-products, allowing them to be used with a wide range of substrates. Oxime curing silicones are a commonly used weather resistant neutral curing sealant, producing methyl ethyl ketoxime (MEKO), also known as butan-2-one oxime, as a by-product upon curing. While MEKO is non-corrosive, it is important to understand the significant health risks that are associated with exposure to this substance.

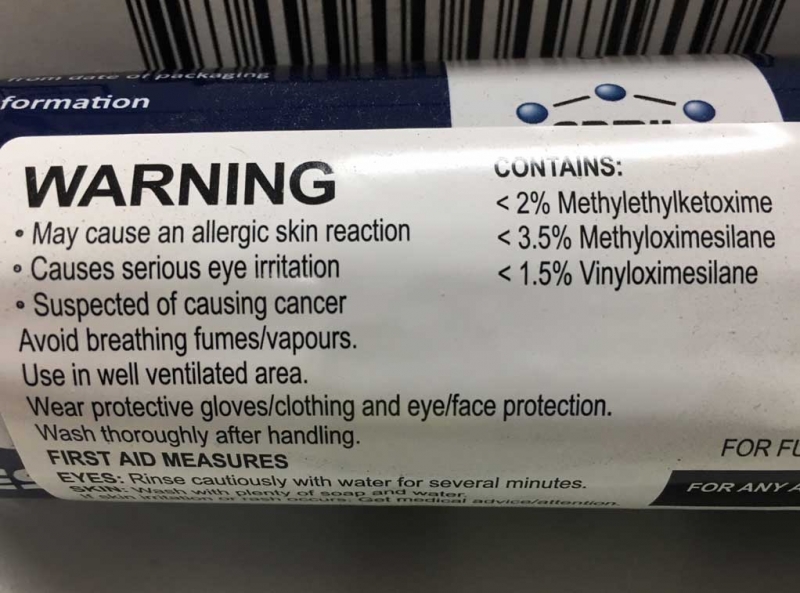

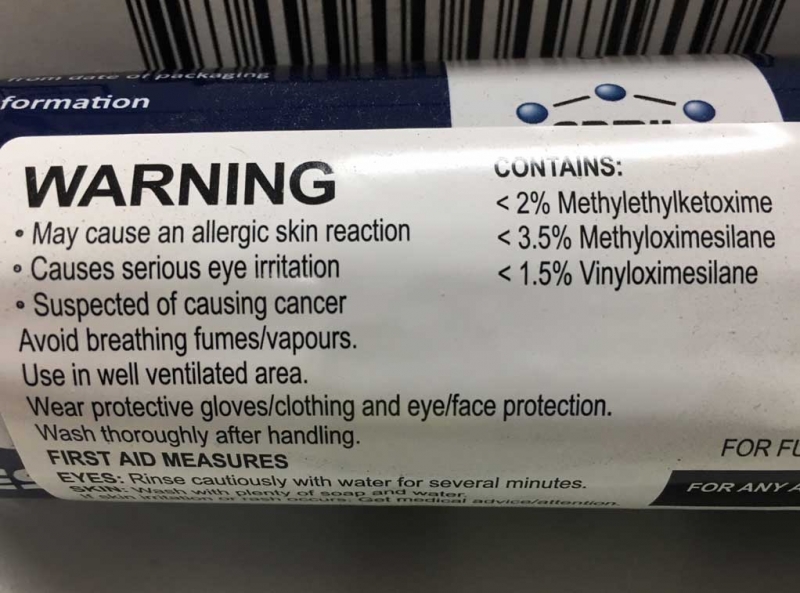

Hazardous chemicals associated with silicone wet seals

The short-term MEKO exposure risks from using oxime silicone sealants are associated with its acute toxicity upon skin contact, eye contact or inhalation [1, 2]. At low concentrations generated from oxime cure, skin contact may cause some skin irritation or facilitate an allergic dermal reaction. Eye contact is severe, causing serious eye irritation upon contact with fumes and irreversible eye damage upon concentrated contact [3]. While the acute toxicity through inhalation is classified as low, respiratory irritation may occur along with significant long exposure risks. Acute oral toxicity is low, but is not as relevant for sealant applications.

Even more concerning is the carcinogenicity of MEKO over a long exposure period. MEKO is classified as a Category 3 carcinogen by Safe Work Australia [1, 2]. Substances with this classification usually carry an associated ‘suspected of causing cancer’ warning in accordance with Australian Work Health and Safety (WHS) legislation. The carcinogenicity study exposed rats to 374 ppm doses via inhalation over 18 months [3]. Upon the closing of the study, degeneration of the respiratory system was observed as well as significant increased incidence of hepatocellular carcinomas, the most common kind of liver tumour [3]. These results, along with other studies of MEKO, are strong indications of the carcinogenicity and long term exposure risks of MEKO.

It is important to understand the risks associated with using wet silicone sealants such that they can be minimised and effectively controlled. The maximum MEKO exposure limit recommended by the American Industrial Hygiene Association is 36 mg/m3 (10ppm) [2]. Workspaces must be well ventilated to keep the concentration of MEKO below this level, along with all other personal protective equipment recommended by the sealant manufacturer, in order to use oxime based sealants in a safe manner. While there are other neutral curing silicones being developed that have lower carcinogenic risk, including alkoxy and amine curing sealants, each continue to produce by-products that are harmful to human health. Inherently, the use of any wet sealant constitutes some form of exposure risk to human health and safety.

While exposure limits and personal protective equipment provide a basic level of risk reduction, those familiar with the Hierarchy of Hazard Controls will know that elimination and substitution are more favourable and effective methods of risk reduction. Reducing the quantity of wet sealant used can substantially reduce workplace risk by reducing the amount of toxic by-products released into the surroundings. A suitable replacement for wet silicone seals are dry gap sealing with a solid silicone join.

Jehbco’s Quick Joint Extrusion is a solid silicone dry seal that does not produce any vapours and has excellent binding strength and better durability than wet seals. As a wet seal replacement, quick joint silicone also minimises installation time significantly and provides a polished, more visually appealing finish to the join. Because the installation time is reduced, the workplace exposure to wet sealant by-products is also reduced significantly. A lower exposure time further minimises health risk and promotes a safer, more productive working environment.

REFERENCES

- Safe Work Australia. Hazardous Substances Information System (HSIS). [cited 16 April 2018]; Available from: http://hsis.safeworkaustralia.gov.au/HazardousSubstance.

- National Industrial Chemicals Notification and Assessment Scheme. HUMAN HEALTH TIER II ASSESSMENT FOR 2-Butanone, oxime CAS Number: 96-29-7. [cited 16 April 2018]; Available from: https://www.nicnas.gov.au/chemical-information/imap-assessments/imap-assessment-details?assessment_id=103#cas-A_96-29-7.

- REACH Dossier. Butanone Oxime (96-29-7). [cited 16 April 2018]; Available from: http://echa.europa.eu/web/guest/information-on-chemicals/registered-substances.