Jehbco Silicones, a leading manufacturer in the silicone extrusion industry, has always prioritised precision and efficiency in its production processes. In pursuit of these goals, the company has integrated three cutting-edge Servo-Torq® Standard rotary cutting systems from Gillard Cutting Technology into its operations. The ST-MT/50C models in use at Jehbco are engineered to handle the rigorous demands of cutting silicone extrusions, such as tubing, with unparalleled accuracy and speed.

Superior Cutting Capabilities

The primary advantage of the Servo-Torq® ST-MT/50C models lies in their ability to deliver high-speed cutting without compromising on precision. These machines are capable of making up to 2000 cuts per minute, a feat that significantly enhances production efficiency. Whether dealing with small or large batches, Jehbco can now ensure that cutting processes keep pace with the extrusion lines, eliminating bottlenecks and improving overall throughput.

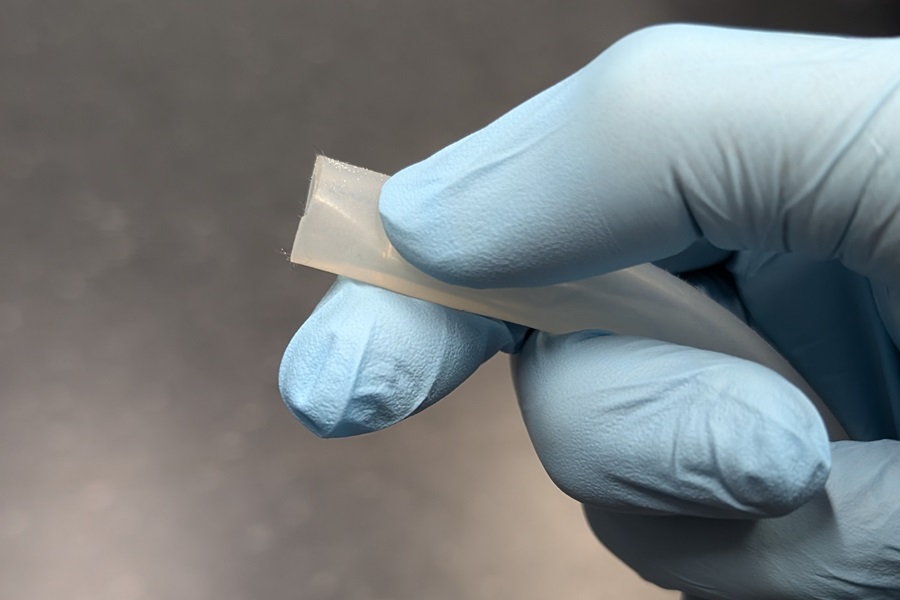

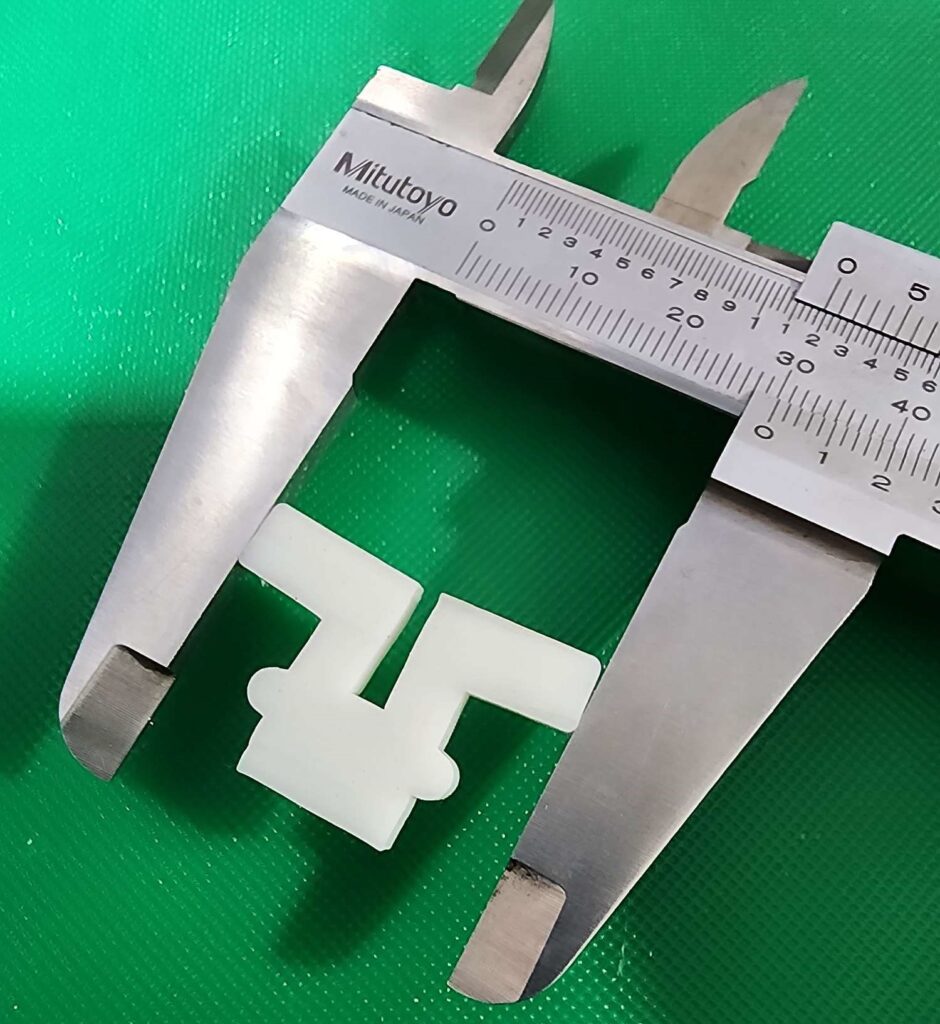

Moreover, the ST-MT/50C models are designed to handle a variety of extrusion sizes. With the capacity to cut extrusions with outer diameters (OD) of up to 50 mm, these machines offer versatility that is critical for Jehbco’s diverse range of products. The ability to manage both thin-walled tubing and solid cords with equal ease makes these machines indispensable in a high-mix production environment.

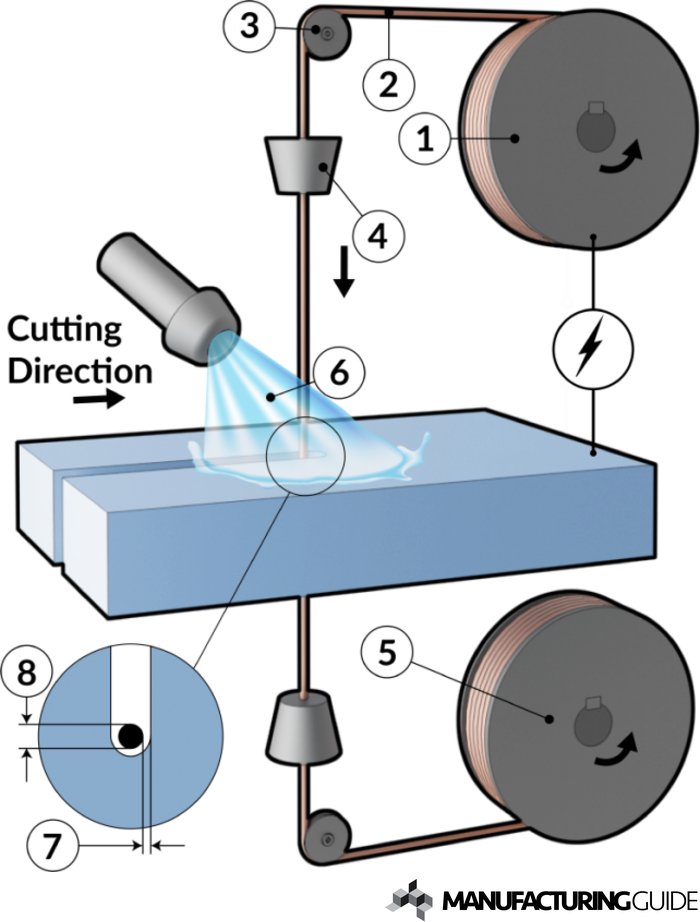

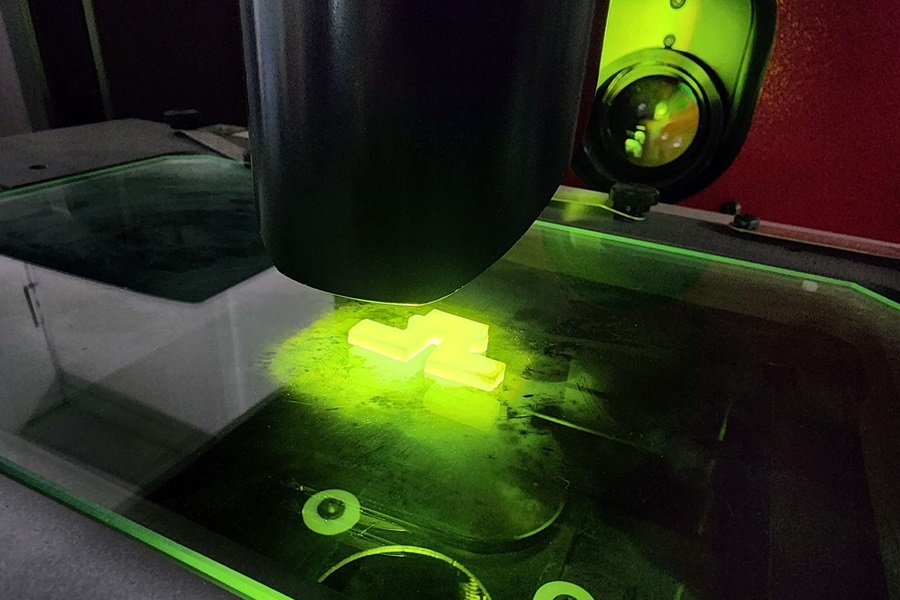

Figure 1. Servo-Torq® Standard rotary cutter system (Model ST-MT/50C) with Accra-Feed™ UA75 caterpillar infeeder/puller.

Precision and Control

Precision is another hallmark of the Servo-Torq® rotary cutting systems. The machines are equipped with a high-speed “flying knife” blade driven by a 5.5 kW brushless AC servo motor, which ensures clean, accurate cuts every time. The digital servo drive system, featuring Lenze i700 multi-axis control, offers precise torque and speed regulation, further enhancing cutting accuracy. This level of control is essential for maintaining the stringent quality standards that Jehbco’s clients expect.

The inclusion of the Accra-Feed™ UA75 caterpillar infeeder/puller system further refines the cutting process. This component uses twin 2.3 Nm AC brushless servo motors to maintain consistent line speeds, which is crucial for ensuring that cut lengths remain uniform. The system’s ability to hold speed within ±0.1% of the maximum line speed is particularly beneficial when producing long, continuous runs of extrusions.

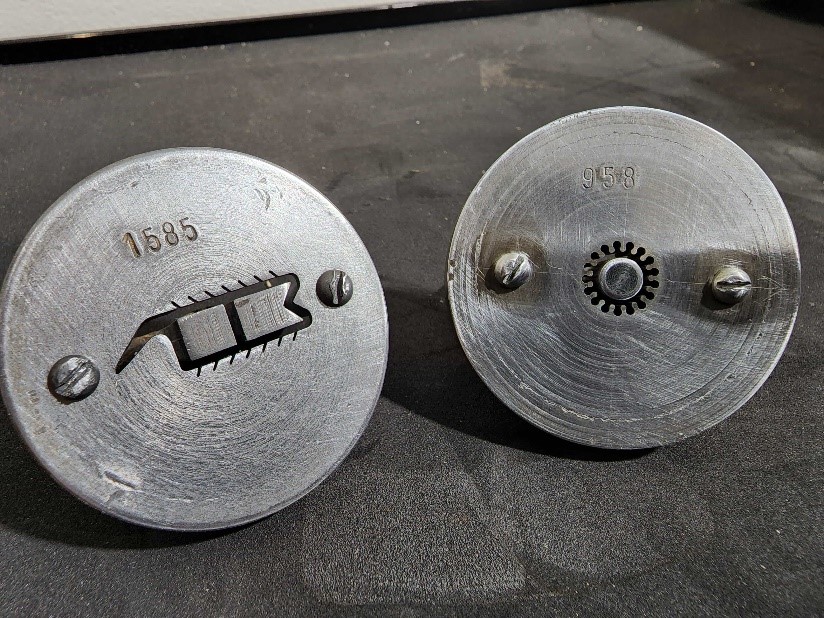

Figure 2. One of three Gillard cutting machines in use at Jehbco Silicones.

User-Friendly Operation and Safety

Despite their advanced capabilities, the Servo-Torq® ST-MT/50C machines are designed with user convenience in mind. The Siemens TP700 Comfort touch-screen control panel offers an intuitive interface, allowing operators to easily set cut lengths, batch quantities, and caterpillar belt speeds. This interface supports Jehbco’s goal of minimising downtime by enabling quick adjustments and real-time monitoring of the cutting process.

Safety is another critical aspect of these machines. The Servo-Torq® ST-MT/50C models are equipped with full safety guarding and meet all relevant EN standards, ensuring a safe working environment for operators. The machines also come with an emergency stop button, cutter and caterpillar-on indicator lamps, and a power-on indicator lamp, providing clear and immediate feedback on the machine’s status.

Conclusion

The integration of the Servo-Torq® ST-MT/50C cutting machines at Jehbco Silicones represents a significant enhancement to their production capabilities. With the ability to perform up to 2000 cuts per minute and handle extrusions with ODs of up to 50 mm, these machines ensure that Jehbco can meet its customers’ demands for precision, quality, and efficiency. As a result, Jehbco is well-positioned to maintain its leadership in the silicone extrusion industry, delivering high-quality products that meet the most stringent standards.

References

- https://www.gillardcutting.com/applications/rubber-extrusion

- https://www.gillardcutting.com/downloads/datasheets/Servo-Torq_LT__MT_Combi_DD_datasheet.pdf